Self-Standing Pneumatic Support

- Overview

- Features

- Performance

- Specifications

- Options & Accessories

- Order

- Resources

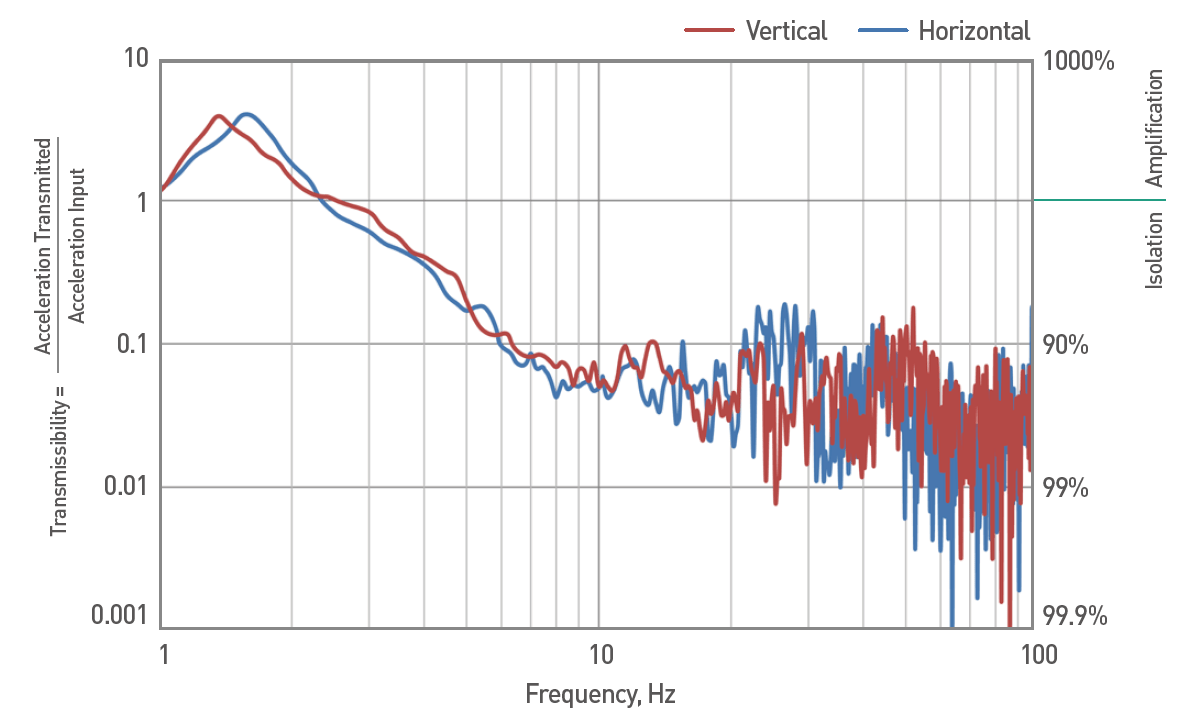

The primary goal of designing vibration isolators is to lower the natural frequency of isolators as low as possible,

in order to filter ambient vibrations in buildings, before the vibrations can reach and disturb the optical tops.

Our integrated pneumatic supports achieve in isolating the low frequency vibrations through the dual-chamber pneumatic isolators and outstanding damping technology.

Dual Chamber Design

The pneumatic vibration is consisted of two chambers that are uniquely designed to lower its resonant frequency

for the better vibration isolation performance in the low-frequency range and increase damping efficiency.

The size of an air chamber is optimized and sealed with a ultra-soft rolling diaphragm and a piston,

softening the stiffness to further improve the vertical vibration isolation performance.

A gimbal support of the pneumatic isolator as a mechanical filter system acts as a gimbal

to minimize friction and reduce horizontal displacements.

Superior Damping

The second chamber is a damping chamber which is linked with the air chamber through a orifice. As the air chamber creates the restoring force,

the air flows into the damping chamber, and the orifice dissipate the energy in the air, damping the system. As the piston moves up and down,

air is forced to move through the orifice, producing a damping force on the payload. This type of damping is strong for large displacements

of the piston and less for small displacements. This allows for fast settling time of the payload, without compromising small amplitude

vibration isolation performance. The orifice installed between the air chamber and the damping chamber quickly restricts

the movement of the optical table top or the external force applied to the optical table top.

Automatic Leveling - Leveling Valves

The high-performance leveling valves automatically relevel an optical table top, offering a wide range of leveling valves options, starting from the standard

leveling valves with leveling repeatability of ±1.0 mm to the precision leveling valves with leveling repeatability of ±0.05 mm. If the settling time, leveling

accuracy and leveling repeatability are required to meet equipment specifications, then the precision leveling valves should be selected.

80% - 99% vibration isolation at 10 Hz

| Vibration Isolation System | Pneumatic Isolation System | ||||||||||||

| Resonant Frequency | 1.2–1.7 Hz | ||||||||||||

| Vibration Isolation at 10 Hz | 80–99% | ||||||||||||

| Maximum Load Capacity | 100–3000 kg | ||||||||||||

| Automatic Leveling | Yes | ||||||||||||

| Accuracy of Leveling Repeatability | ±1.0 mm for Standard Leveling Valve ±0.05 mm for Precision Leveling Valve |

||||||||||||

| Height Adjustement | ±20 mm | ||||||||||||

| Required CDA | 4–6 bar | ||||||||||||

Options

Accessories

Related Products

Ordering Information

Ordering Chart

| Model No. | Dimensions (ØD x h)(mm) | Maximum Payload capacity (kg/1set) |

|---|---|---|

| DVIO-S-M4(h) | 216 x h | 500 |

| DVIO-S-L4(h) | 216 x h or 267 x h | 1000 |

| DVIO-S-L6(h) | 1500 | |

| DVIO-S-P4(h) | 2000 | |

| DVIO-S-P6(h) | 3000 |