Non-magnetic Stainless Steel Optical Top

- Overview

- Features

- Performance

- Specifications

- Options & Accessories

- Resources

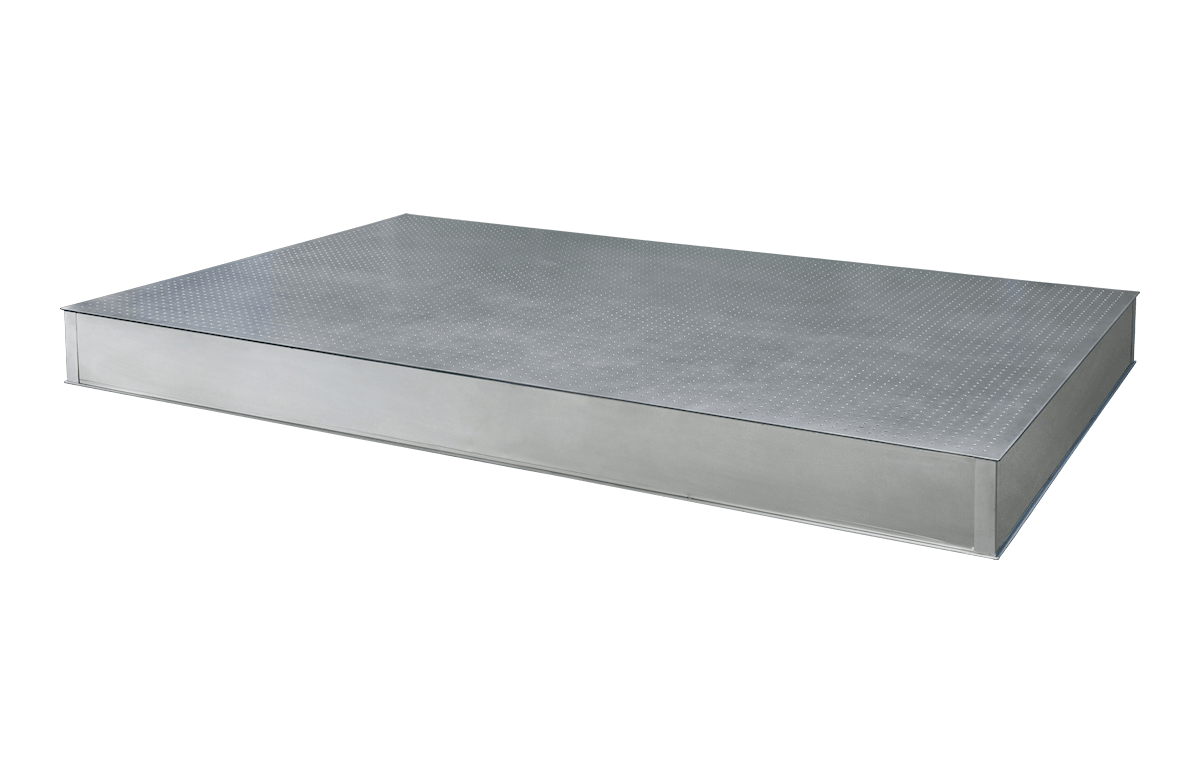

Non-magnetic Stainless Steel Optical Top

Non-magnetic stainless steel optical top is made of 304 series non-magnetic stainless steel for clean rooms

and non-magnetic applications. The non-magnetic stainless steel optical top provide same features and

benefits that are present on the research grade optical tops. The stainless steel optical top features the finest

performance level of broadband damping that effectively minimizes relative displacement in a wide

frequency, superior structural damping level and ultimate rigidity.

All stainless steel construction

0.25 mm thick honeycomb stainless steel layers are corrugated to

increase its core density and minimize its cell size; These corrugated

honeycomb stainless steel steel layers are vertically epoxy bonded with

stainless steel top skins, stainless steel steel bottom skins and stainless

steel sidewalls to offer static and dynamic rigidity for the

outstanding performance level.

Steel Honeycomb Core Structure

The corrugated honeycomb steel layers are vertically expoxy bonded with a stainless steel top skin,

a carbon steel bottom skin and sidewalls, increasing its core density and minimizing its cell size.

This steel honeycomb core structure provides the highest core density and the smallest honeycomb core cell size, offering maximum static and dynamic rigidity.

Smallest Honeycomb Core Cells

Our steel honeycomb core yields in the highest core density and the smallest honeycomb cell size 2.9㎠, offering the superb rigid table top. As the smallest honeycomb cells contributing to increase the elastic selection modulus, the natural frequency of the optical table tops increases, which the table top is less likely to respond to external forces and unfiltered vibration. Moreover, the higher natural frequency minimizes vibration intensities and deflection under loads, which is critical for conducting optical experiments.Our optical table top is all steel constructed, ensuring the long term thermal stability.

Individually Sealed Mounting Holes

Spill-proof and non-corrosive nylon cups are individually epoxy-bonded under each mounting hole to prevent spilling of liquids from contaminating the honeycomb core.

Tapped and Clean Surface

The table top surface is precision tapped and delicately sanded to provide a non-reflecting surface. Moreover, the surface is completely cleaned to remove residual metal particles and cutting fluids.

Custom Optical Table Tops

We offer customization of optical table tops to meet a variety of customers' needs.

Compliance curve was measured on

2400 x 1200 x 300mm Research Grade optical top

| Construction | |||||||||||||

| Core | Steel Honeycomb core structure, 0.25mm (1in.) thick foil | ||||||||||||

| Core Cell Size | 3.2㎠ (0.5 in²) | ||||||||||||

| Core Shear Modulus | 19339kgf/cm2 (275,000 psi) | ||||||||||||

| Surface Flatness | ±0.1mm (±0.004 in.) over 600 mm² (2 ft.) | ||||||||||||

| Top Skin | 304 series ferro non-magnetic stainless steel 4.0 mm thick | ||||||||||||

| Bottom Skin | 4.5 mm thick 304 series non-magnetic stainless steel | ||||||||||||

| Side Walls | 2.0 mm thick 304 series non-magnetic stainless steel with damped composite wood | ||||||||||||

| Mounting Holes | M6-1.0 (1/4-20) | ||||||||||||

| Mounting Hole Grid | 25 mm (1in.) grid | ||||||||||||

| Mounting Hole Borders | 37.5 mm (1.5 in.) | ||||||||||||

| Mounting Holes Sealing | 21 mm deep Clean cylindrical cup, chemical resistant nylon 66 material | ||||||||||||

| Damping Method | Broadband damping | ||||||||||||

| Maximum Relative Motion | 1.2 x 10^-10mm (2400 x 1200 x 300 mm) | ||||||||||||

| Deflection Under Load | 1.1 x 10^-5mm (2400 x 1200 x 300 mm) | ||||||||||||

| Maximum Dynamic Deflection Coefficient |

2.1 x 10^-5 (2400 x 1200 x 300 mm) | ||||||||||||

Options

Research Grade Optical Table Top

Non-magnetic Stainless Steel Optical Table Top

Custom Optical Table Top

We offer custom size and shapes of optical table tops.

Pneumatic Support with Tie-Bars & Casters

Pneumatic Support - Self-Standing Type

Rigid Support with Tie-Bars & Casters

Rigid Support - Self-Standing Type

Joined Optical Tables

Accessories

DOTS - Overhead Shelf

DOTE - Table Enclosure

DCB - Clean Booth

DB - Dark Booth

Faraday Cage

DAC-30 - Air Compressor