Active Vibration Isolation Systems

Case Studies

Case Studies

1. Measurement Details

- Measurement Date

April 6, 2016 - Measurement Devices

1. LAN-XI Data Acquisition Hardware

– Brüel & Kjæ r 3050-B-040

2. Data Analysis Software

– Brüel & Kjæ r PULSE LAB SHOP 14

3. Sensors

– PCB Accelerometer

– Model: 393B05 - Measurement Location

5th Floor - Measurement Setup

Bandwidth: 0 – 100 Hz

Lines: 400

Window: Hanning

Averaging: Fast Fourier Transform Spectrum Averaging

Amplitude Units: m/s2

Spectral Unit: RMS

2. Equipment Information

- Manufacturer

HITACHI - Model

SEM SU8010 - Floor Vibration Specification

VC-E

3. Vibration Isolation System

Model: DVIA-MB1000

| Model | DVIA-MB1000 | DVIA-MB3000 | DVIA-MB6000 | |

|---|---|---|---|---|

| Platform Dimensions (L x W x H) | Custom-made | |||

| Load Capacity | 500 - 1700 kg | 1500 - 3500 kg | 3000 - 6000 kg | |

| Actuator | Electromagnetic Actuator | |||

| Maximum Actuator Force | Vertical: 40 N, Horizontal: 20 N | Vertical: 80 N, Horizontal: 40 N | ||

| Degrees of Freedom | 6 degrees | |||

| Active Isolation Range | 0.5 - 100 Hz | |||

| Vibration Isolation at 1 Hz | ≥90% | |||

| Input Voltage (V) | AC100 - 240V / 50 - 60 Hz / 1A | |||

| Power Consumption (W) | Maximum 110W, <50 W in normal operation | |||

| Operating Range | Temperature (°C) | 5 - 50 °C | ||

| Humidity (%) | 20 - 90% | |||

| Required Air Pressure | ≥ 0.5 MPa (≥ 5 bar) | |||

4. Installation Photo

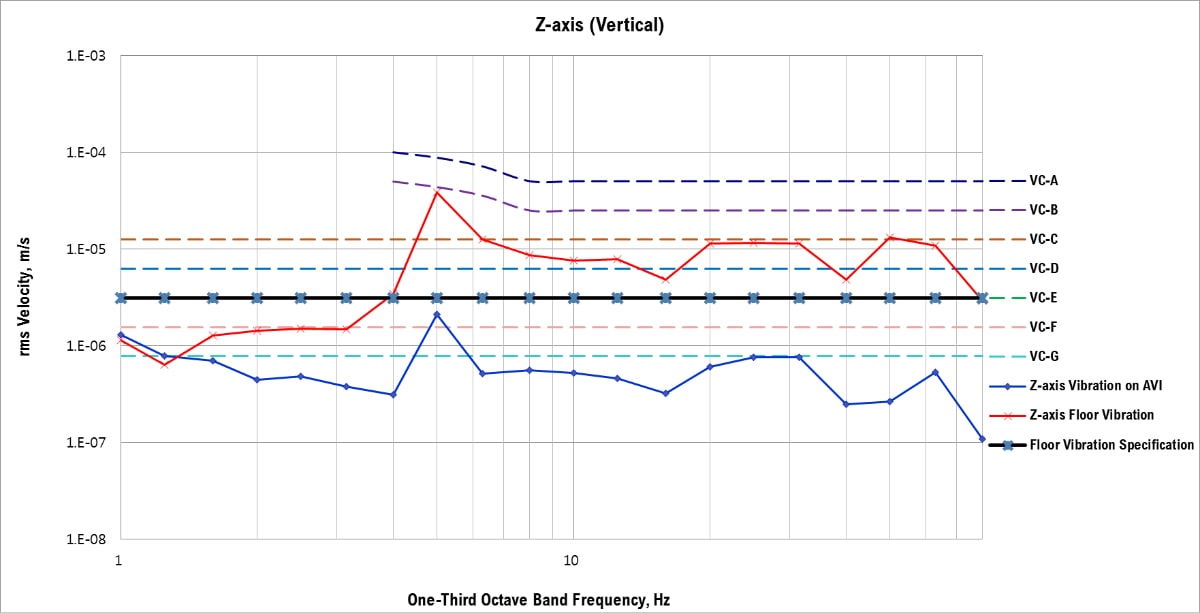

5. Results – Vibration Criterion Curves

VC Curves, Z-axis (Vertical)

AVI = Active Vibration Isolation

The active vibration isolation system reduced the vertical floor vibration from VC-B to VC-E.

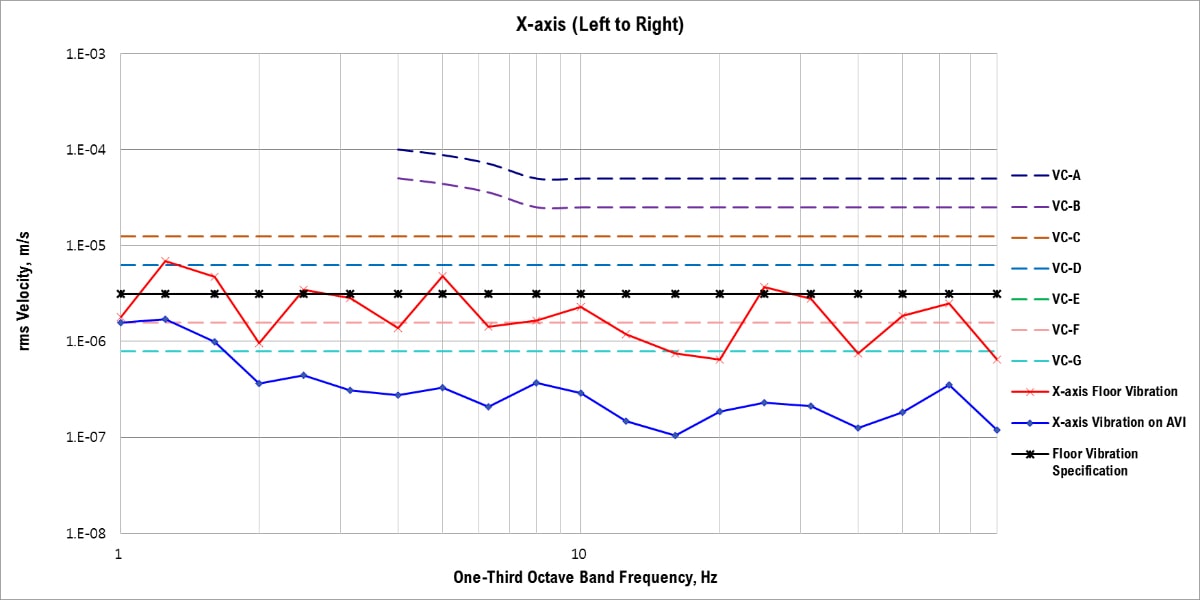

VC Curves, X-axis (Left to Right)

AVI = Active Vibration Isolation

The active vibration isolation system reduced the vertical floor vibration from VC-C to VC-F.

VC Curves, Y-axis (Front to Back)

AVI = Active Vibration Isolation

The active vibration isolation system reduced the vertical floor vibration from VC-B to VC-F.

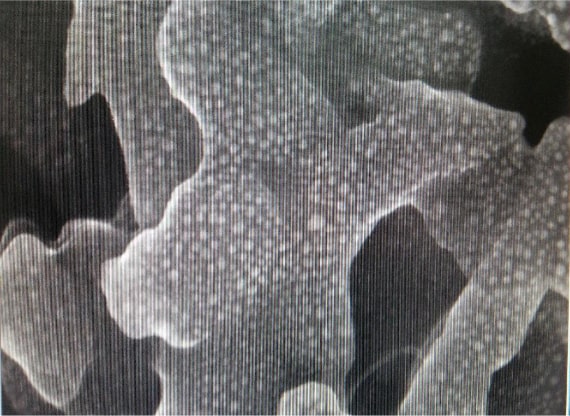

6. Results – Active Isolation Off vs Active Isolation On

Active Vibration Isolation Off

HV:15.00 kV

Mag: 100 000 x

Linewidth: 500 nm

Active Vibration Isolation On

HV:30.00 kV

Mag: 100 000 x

Linewidth: 500 nm

Active Vibration Isolation Off

HV:15.00 kV

Mag: 100 000 x

Linewidth: 500 nm

Active Vibration Isolation On

HV:30.00 kV

Mag: 100 000 x

Linewidth: 500 nm

7. Reference

Generic Vibration Criteria

| Criterion Curve | Description | Amplitude1) μm/s (in/s) | Detail Size2) μm |

|---|---|---|---|

| Workshop (ISO) | Distinctly perceptible vibration, Appropriate to workshops and non-sensitive areas. | 800 (32,000) | N/A |

| Office (ISO) | Perceptible vibration. Appropriate to offices and non-sensitive areas. | 400 (16,000) | N/A |

| Residential Area (ISO) | Barely perceptible vibration. Appropriate to sleep areas in most instances. Usually adequate for computer equipment, hospital recovery rooms, semiconductor probe test equipment, and microscopes less than 40x. | 200 (8,000) | 75 |

| Operating Theatre (ISO) | Vibration not perceptible. Suitable in most instances for surgical suites, microscopes to 100x and for other equipment of low sensitivity. | 100 (4,000) | 25 |

| VC-A | Adequate in most instances for optical microscopes to 400x, microbalances, optical balances, proximity and projection aligners, etc. | 50 (2,000) | 8 |

| VC-B | Appropriate for inspection and lithography equipment (including steppers) to 3pm line widths. | 25 (1,000) | 3 |

| VC-C | Appropriate standard for optical microscopes to 1000x, lithography and inspection equipment (including moderately sensitive electron microscopes) to 1μm detail size, TFT-LCD stepper/scanner processes. | 12.5 (500) | 1-3 |

| VC-D | Suitable in most instances for demanding equipment, including many electron microscopes (SEMs and TEMs) and E-Beam systems. | 6.25 (250) | 0.1-0.3 |

| VC-E | A challenging criterion to achieve. Assumed to be adequate for the most demanding of sensitive systems including long path, laser-based, small target systems, E-Beam lithography systems working at nanometer scales, and other systems requiring extraordinary dynamic stability. | 3.12 (125) | <0.1 |

| VC-F | Appropriate for extremely quite research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. | 1.56(62.5) | N/A |

| VC-G | Appropriate for extremely quite research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. | 0.78(31.3) | N/A |

- As measured in one-third octave bands of frequency over the frequency 8 to 80 Hz (VC-A and VC-B) or 1 to 80 Hz (VC-C through VC-G).

- The detail size refers to line width in the case of microelectronics fabrication, the particle (cell) size in the case of medical and pharmaceutical research, etc, It is not relevant to imaging associated with probe technologies, AFMs, and nanotechnology.

The information given in this table is for guidance only. In most instances, it is recommended that the advice of someone knowledgeable about applications and vibration requirements of the equipment and processes be sought.