Generic Vibration Criteria

Introduction

The vibration criterion (VC) curves, widely used and accepted throughout the world as a basis for evaluating facilities for vibration-sensitive instruments and tools and designing structures that will support vibration-sensitive equipment and process, were developed by Colin Gordon and his associates. Equipment operational problems that caused by vibration, can be prevented if environmental vibration complies with the vibration criterion curves appropriate to the equipment specific vibration criteria.

Vibration Criterion Curves (VC Curves)

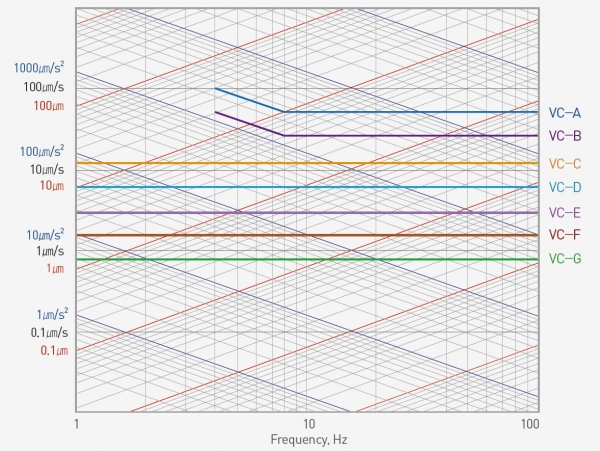

The vibration criterion criteria takes the form of a set of one-third octave band velocity spectra labeled vibration criterion curves VC-A through VC-G, illustrated in Figure 1 and numerically defined in Table 1. The vibration is expressed in terms of its root-mean-square (rms) velocity.

Figure 1

What are Octave Bands?

Octave Bands provide a method of splitting

the vibration levels into smaller segments

known as Octaves, identifying different

vibration levels across individual frequencies.

One third Octave Bands are mainly used environmental

and noise control applications. Each Octave Band is

further split into three called one third Octave Band,

providing a more detailed view of vibration levels. The

entire frequency range is divided into sets of frequencies

known as bands. Each band represents a specific range

of frequencies. As the band increases, the upper band

frequency is twice the lower band frequency.

![Graph-octave-Bands-Generic-Vibration-Criteria Octave Bands - Frequency [Hz] Graph](https://www.daeilsys.com/wp-content/uploads/elementor/thumbs/Graph-octave-Bands-Generic-Vibration-Criteria-ot2i5khk4bsk13cd88zk0woe8svs0u6k94ctga1d3y.jpg)

| Criterion Curve | Description | Amplitude¹ ㎛/s (in/s) |

Detail Size² ㎛ |

|---|---|---|---|

| Workshop (ISO) | Distinctly perceptible vibration. Appropriate to workshops and non-sensitive areas. | 800 (32,000) | N/A |

| Office (ISO) | Perceptible vibration. Appropriate to offices and non-sensitive areas. | 400 (16,000) | N/A |

| Residential Area (ISO) | Barely perceptible vibration. Appropriate to sleep areas in most instances. Usually adequate for computer equipment. hospital recovery rooms. semiconductor probe test equipment. and microscopes less than 40x. | 200 (8,000) | 75 |

| Operatig Theatre (ISO) | Vibration not perceptible. Suitable in most instances for surgical suites. microscopes to 100x and for other equipment of low sensitivity. | 100 (4,000) | 25 |

| VC-A | Adequate in most instances for optical microscopes to 400x, microbalances, optical balances, proximity and projection aligners, etc. | 50 (2,000) | 8 |

| VC-B | Appropriate for inspection and lithography equipment (including steppers) to 3㎛ line widths. | 25 (1,000) | 3 |

| VC-C | Appropriate standard for optical microscopes to 1000x, lithography and inspection equipment (including moderately sensitive electron microscopes) to 1㎛ detail size. TFT-LCD stepper/scanner processes. | 12.5 (500) | 1-3 |

| VC-D | Suitable in most instances for demanding equipment. including many electron microscopes (SEMs and TEMs) and E-Beam systems. | 6.25 (250) | 0.1-0.3 |

| VC-E | A challenqing criterion to achieve. Assumed to be adequate for the most demanding of sensitive systems including long path. laser-based. small target systems. E-Beam lithography systems working at nanometer scales. and ofher systems requiring extraordinary dynamic stability. | 3.12(125) | <0.1 |

| VC-F | Appropriate for extremely quite research spaces: generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion. only for evaluation. | 1.56 (62.5) | N/A |

| VC-G | Appmpriate for extremely quite research spaces; generally difficult to achieve in most instances. especially cleanrooms. Not recommended for use as a design criterion. only for evaluation. | 0.78 (31.3) | N/A |